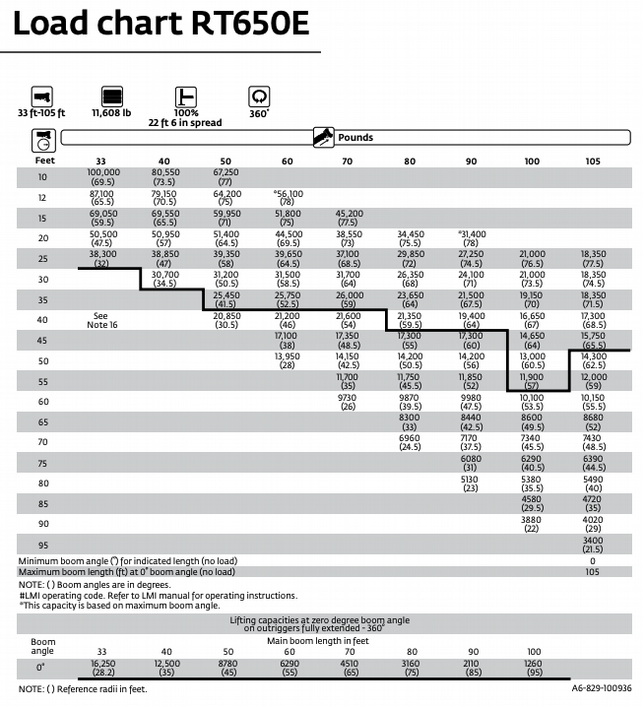

Load on one sling = Vertical load/sin(60). Įach sling is subject to a load of 500 tonnes Following tables depicts the comparison of loading at 90®, 60®, 30®. Loading changes drastically with the sling angle. The point of suspension of the equipment should always be in line with the centre of gravity of the equipment to avoid tilting of the equipment. In the above load assessment, we assumed the sling angle to be 90 degrees. In this case, the lifting beam is subjected to 1000 tonnes (Note: the two pad eyes that transfer the load is subjected to 500 tonnes each). The sling wire transfers the load to the lifting beam. There are four wires used, hence each wire is subjected to 250 tonnes (For time being we will ignore effects due to sling angle). The sling wires transfer the load to the lifting beam. Hence each pad eye is subjected to a load of 250 tonnes. In the above lifting arrangements, the 1000 tonne module is lifted using 4-pad eyes. To analyse whether a lifting gear can withstand a given load, we must first estimate the load imposed on the lifting gear. Hence all the lifting gears involved in the load transfer must be able to withstand the load imposed during the lifting operation. (In general, these are called as lifting gears). Load of the equipment is transferred to the crane through the lifting pad eyes, spreader beams, lifting wires, shackles etc.

Let us discuss how the load of the module is transferred to the crane. The most basic requirement is the lifting crane supposed to be of a capacity higher than 1000 tonnes (As per norms, crane safe working load to be at least 1.25 times the weight of the equipment). Let’s consider the weight of the module is about 1000 Tonnes. Let’s assume the weight of the module is about 1000 Tonnes. We will address these challenges and will explain in detail, how to tackle these problems.įor example, a process module to be installed on FPSO. Offshore jacket platform installation in the offshore site.

Offshore module lifting: Offshore vessels like FPSO, FLNGs have various process modules like chemical injection package, sulphate removal system, water injection system, etc.Equipment exceeding the capacity of the shore crane is usually lifted using floating craneįigure 1: Offshore lifting Examples of offshore lifting Shore crane with limited lifting capacity: Generally shore crane lifting capacity is only up to 200 tonnes.Sometimes, when a vessel is berthed port side, but it’s required to lift up or install equipment in starboard side, which cannot be reached by the shore crane When shore crane cannot perform the lifting.

Offshore lifting is a common operation in offshore construction or installation projects at sea.

0 kommentar(er)

0 kommentar(er)